Modern industrial applications depend heavily on precision and efficiency in their processes. Among the tools that help achieve these benchmarks, high-pressure gear pumps stand out as essential components in a wide range of industries, from manufacturing to oil and gas. Known for their durability, reliability, and ability to handle high pressures, these mechanisms are a powerhouse of industrial operations. This guide will explore the critical role of high-pressure gear pumps, how they function, and what industries benefit most from their use. It will also examine the importance of choosing the right gear pump manufacturer for your application needs.

What Are High-Pressure Gear Pumps?

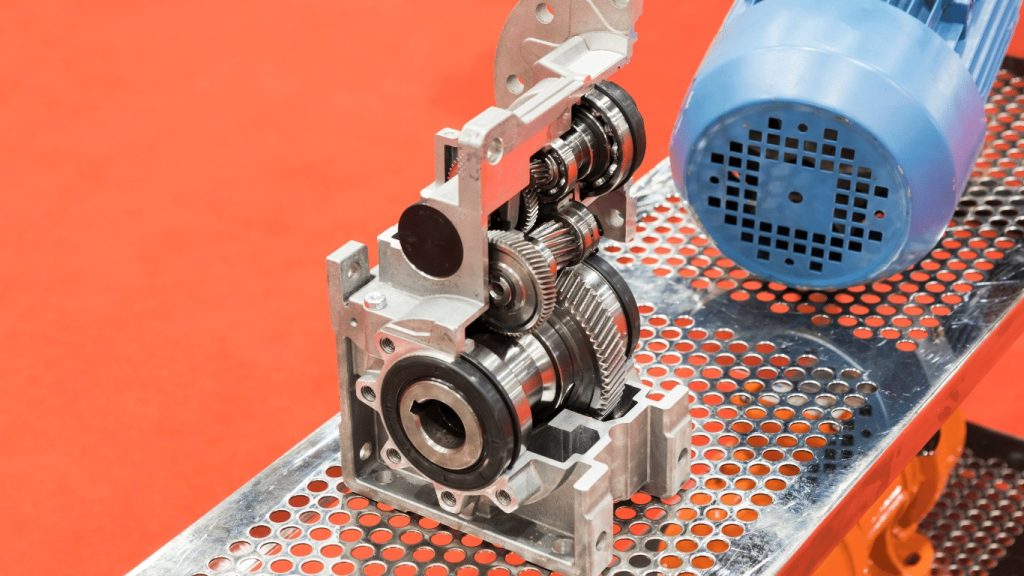

A high-pressure gear pump is a positive displacement pump known for its ability to deliver a consistent flow of fluids, even at high pressures. The pump works by trapping fluid between its two rotating gears and moving it through the system with remarkable precision.

This type of pump is specifically designed to handle viscous or high-pressure fluids, making it an indispensable tool for applications where standard pumps might fail. Whether you’re pumping hydraulic oil, fuel, or chemical substances, high-pressure gear pumps offer consistent performance while withstanding challenging operational conditions.

Key features include:

- Tolerance for fluids with varying viscosity

- Ability to operate at high pressures without compromising performance

- Low maintenance requirements, making them cost-effective over time

How Do High-Pressure Gear Pumps Work?

High-pressure gear pumps operate with a simple yet highly effective mechanism. Here’s a step-by-step breakdown of their functioning:

- Fluid Enters the Pump

The gears in the pump rotate to create a void, pulling fluid into the pump chamber.

- Fluid is Trapped Between the Gears

The fluid is trapped within the spaces between the gear teeth and the pump casing, preventing backflow.

- Fluid is Pressurized and Delivered

As the gears rotate, the fluid is pressurized and pushed out through the discharge port.

The most notable advantage of this setup is its ability to handle high-pressure requirements without losing efficiency.

Applications of High-Pressure Gear Pumps Across Industries

The versatility of high-pressure gear pumps allows them to be utilized in various industrial settings. Below are some of the most prominent industries that benefit from these pumps:

- Hydraulic Systems

Hydraulic systems are a backbone of many industries, including construction, manufacturing, and automotive. High-pressure gear pumps ensure smooth operations in hydraulic machinery by delivering consistent pressure and flow.

- Oil and Gas

High-pressure gear pumps are widely used in oil and gas processes for tasks like fuel transfer and chemical injection. These pumps can handle the high demands of transporting viscous fluids with accuracy and reliability.

- Chemical Processing

The chemical industry often deals with corrosive and viscous substances. High-pressure gear pumps built with resistant materials like stainless steel are ideal for handling aggressive chemicals without system failure.

- Food and Beverage

Sanitary models of gear pumps are employed in food processing and beverage manufacturing. They ensure the safe and consistent transfer of oils, syrups, and other ingredients while meeting regulatory standards.

- Aerospace and Defense

Complex machinery in aerospace and defense often relies on high-pressure systems for optimal performance. Gear pumps provide the durability required for rigorous operational conditions in these critical sectors.

Benefits of Using High-Pressure Gear Pumps

Consistent Delivery at High Pressures

High-pressure gear pumps can operate steadily under demanding conditions without compromising the quality of fluid transfer.

Versatility Across Fluid Types

From thin fuels to viscous oils, gear pumps handle a wide range of fluids, making them adaptable across industries.

Durability and Longevity

Constructed with robust materials, high-pressure gear pumps are designed to endure high pressures, extreme environments, and long operating cycles.

Low Maintenance Requirements

Their relatively simple design ensures that breakdowns are rare, leading to reduced maintenance costs over time.

Compact Design

Despite their powerful capabilities, high-pressure gear pumps are compact, making them easy to integrate into existing systems.

Selecting the Right Gear Pump Manufacturer

Choosing the right gear pump manufacturer is critical to ensuring the efficiency and longevity of your system. Here are some factors to consider when selecting a manufacturer:

- Industry Experience and Expertise

Look for manufacturers with a solid reputation in designing and producing reliable high-pressure gear pumps. Industry experience is often an indicator of quality and innovation.

- Customization Options

Manufacturers that offer customization can tailor the pump’s design to meet the unique requirements of your operation, such as handling specific fluid types or meeting industry standards.

- Material Quality

High-pressure gear pumps require durable materials to operate efficiently under challenging conditions. Ensure the manufacturer uses materials capable of withstanding wear, corrosion, and high pressures.

- Compliance with Standards

Check if the manufacturer adheres to international manufacturing and quality assurance standards, such as ISO certifications.

- After-Sales Support

A reputable manufacturer will provide after-sales support, including maintenance services and availability of spare parts, ensuring long-term operational reliability.

Future Trends in High-Pressure Gear Pumps

The industrial landscape is evolving rapidly, and high-pressure gear pumps are no exception. Future trends include:

- Integration with Smart Technologies

IoT-enabled gear pumps allow for real-time monitoring and diagnostics, enhancing efficiency and reducing downtime.

- Improved Energy Efficiency

Manufacturers are focusing on designs that minimize energy consumption without sacrificing performance.

- Eco-Friendly Materials and Processes

The push for sustainability is leading to the development of gear pumps made with eco-friendly materials and manufacturing practices.

By staying ahead of these trends, industries can maximize the benefits of high-pressure gear pumps while meeting modern operational demands.

Why High-Pressure Gear Pumps Are Indispensable

High-pressure gear pumps are more than just tools; they are vital cogs in the machinery of modern industries. They provide the reliability, efficiency, and flexibility required to handle complex operations across various sectors.

Selecting the right gear pump manufacturer adds yet another layer of assurance, ensuring that your systems will remain efficient and dependable for years to come.

To optimize your industrial operations, understanding and leveraging the power of high-pressure gear pumps is essential.